This post was co-authored by Carissa Aiello.

In the keynote for our annual Pulse conference in May, we spoke about the Customer Success Network. One of the 6 trends in that Network was the spread of Customer Success practices to “real” industries. The Internet of Things is propelling that evolution.

Our friends at PTC are leaders in this transformation, so we’ve spent a lot of time picking their brains. Chief Customer Officer Paul Lenfest says:

The pace of IoT innovation is accelerating and it can be very challenging for manufacturers to bring their customers along at the same speed. With IoT, you can leverage data to not only educate your customers on the new value they can capture but also improve the customer experience and even increase the value they find in your product. Customer Success then becomes critical to smart connected product manufacturers—a competitive must-have—to proactively and rapidly guide clients to value.

IoT has created not only an opportunity but also an imperative to interpret and act on the enormous amounts of data that are being gathered about clients. In this post, we’ll discuss the 6 layers of Customer Success for manufacturers of connected devices.

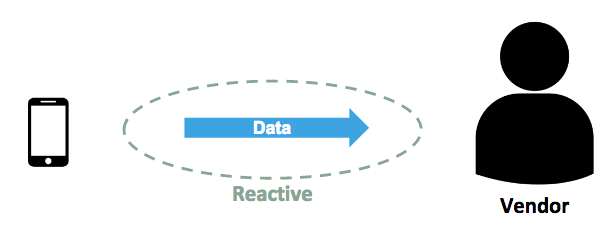

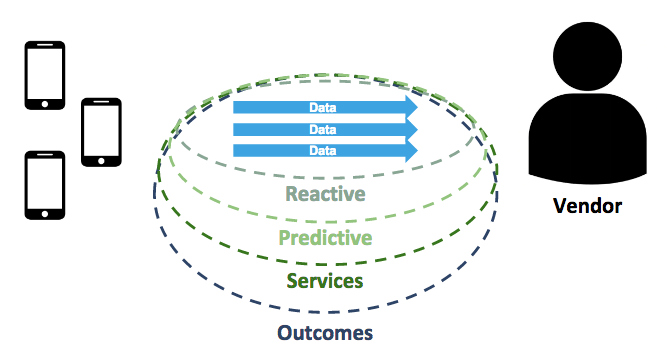

Layer #1: Individual Device

Vendors used to be in the dark about the client experience. They might have seen the results of CSAT surveys after field service calls. They might have gathered qualitative insights about the client experience during a sales meeting. But overall, their visibility was limited.

As vendors collect more data on how devices are being used, they expand their ability to improve the client experience. They can start by being more “reactive” to client needs: e.g. following up when the data signals that a device is malfunctioning. Knowledge not only implies opportunity for the vendor, but also responsibility. If clients know you’re collecting data on them, they’ll expect that you’ll follow up in the right scenarios.

That means that vendors have to:

- Identify new scenarios where intervention makes sense

- Define new roles for handling those scenarios

- Design playbooks for what to do in each scenario

- Identify and track metrics for assessing the results of those playbooks

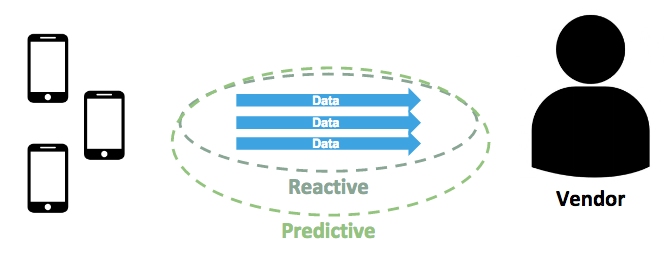

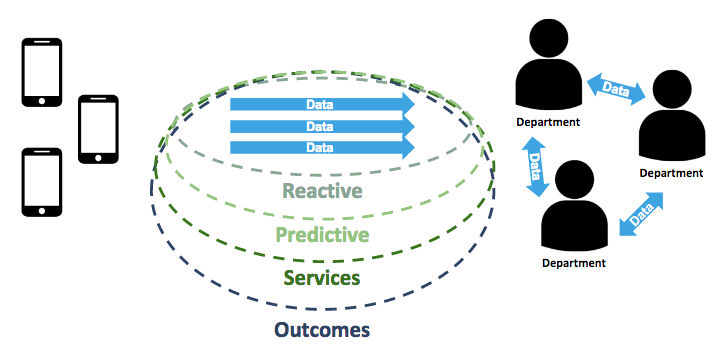

Layer #2: Across Devices

The next layer of Customer Success involves capturing synergies across devices.

A manufacturer providing real-time in-home radon detection may observe unusually high levels of radon in someone’s home. Having designed the “reactive” playbooks in section #1 above, that manufacturer can trigger a technician to call the homeowner and troubleshoot the problem.

However, what if the data shows an abundance of houses in the same area that have high levels of radon? Capturing this trend across clients can allow the manufacturer to deliver even more value for clients, for example, by notifying the necessary regulatory agency in the area to determine the root cause.

Moreover, as a vendor gathers more data across all devices, it can start to predict how the client experience will unfold, and then support the client accordingly. A much-cited Harvard Business Review article describes a manufacturer’s ability to intervene immediately when detecting “risk” in a client relationship: “Knowing that a customer’s heavy use of a product is likely to result in a premature failure covered under warranty, for example, can trigger preemptive service that may preclude later costly repairs.”

Detecting patterns across devices can also enable longer-term improvements. If one device malfunctions, the vendor can provide a software update that fixes the problem across all devices.

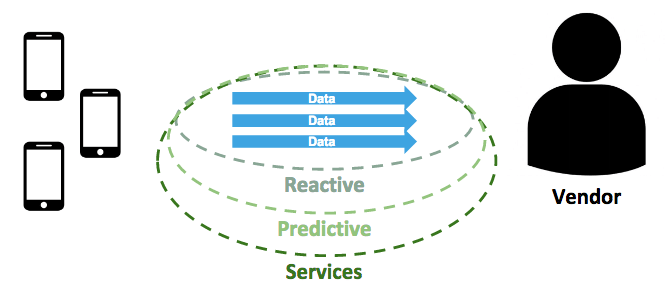

Layer #3: From Devices to Services

Vendors have an opportunity to not merely manufacture devices, but to drive tangible business results for clients through new types of services.

Current services might focus merely on product warranties. But future services can include “Insights as a Service.” Providers can augment point-of-use information gathered from connected devices with external data sets to help their clients make more informed business decisions. In addition, preventative maintenance services can leverage data to prevent problems from escalating, and thus offer higher product performance guarantees or SLAs.

As an example, before innovations in IoT, any time there were warnings of in-flight engine irregularity, airlines would require a long, costly inspection of the entire engine. But today, Rolls Royce’s IoT-enabled jet engines use in-flight data to generate real-time safety assessments, and determine specifically which areas of the engine are in need of maintenance. This generates massive time and cost savings for the airline.

A plethora of other services that drive value for clients are emerging—including remote services (“Can you fix my problem without arranging a service visit?”), services involving augmented reality overlays (“Help me figure out how to fix this myself”), comparative benchmarking (“Am I getting full value out of my devices?”), and education services (“How do I use these more complex devices?”).

Beyond offering services as a supplement to devices, vendors may even forgo charging for their products and instead charge for their consumption. Big Belly once manufactured trash cans for sale, but now it provides trash pick-up as a service—pricing its offering to more closely match the value that clients are deriving.

Layer #4: From Services to Outcomes

Vendors can go one step further by demonstrating to the client that they’ve driven strong outcomes. Clients don’t just want to consume services—they want to achieve a real return-on-investment on their purchase.

Vendors can use point-of-use data to quantify the ROI and also showcase that value in executive meetings with the client or even monthly or quarterly email updates. Demonstrating ROI to the client in this way helps pre-empt the question: “Why are we paying so much money for this service, and do we really need it?” It also paves the way for upsell or cross-sell, since clients are more likely to invest when they’re convinced of the value they’ve already derived.

eCompliance is a workplace safety company that offers Field iD, which tracks equipment on the job site and identifies potential risks to workers. eCompliance is able to track workplace incidents that have been averted through use of its products—meaning they can report back to clients, “Here’s the return on investment you’ve achieved by working with us.”

Once vendors recognize that they’re in the business of driving outcomes for their clients, they realize that they don’t merely have the responsibility to offer a device in a transaction—they must also shoulder the responsibility for change management. Clients of connected devices may have to change their own behaviors and operations.

Driving change and delivering outcomes at the client requires not just the advent of new services, but the development of a new function at the vendor: Customer Success Management. Traditional Services organizations are expanding their ranks to include Customer Success Managers, who take responsibility for driving outcomes for the client—often quarterbacking on the client’s behalf to mobilize resources at other departments within the vendor.

That cross-functional collaboration comprises the next layer of Customer Success.

Layer #5: Across Your Company

Data can help vendors fix a problem or drive an outcome. But even more impactfully, the data collected by devices can help vendors improve their entire delivery model.

A vendor can dramatically improve its operations by marrying data from devices with data from other sources such as Support tickets, Net Promoter Score surveys, and CRM or contract data. You can now do analyses such as, “Is there an opportunity to sell more maintenance contracts among large clients with low NPS ratings but high consumption of the devices and frequent Support interactions?” The results of such an analysis yields insights for departments across the company.

This feedback loop can allow multiple departments to iterate together on the client journey, as McKinsey describes in detail here. Feedback also allows your R&D department to accelerate product improvements.

Arguably, R&D departments at device manufacturers need to have the client in mind even more than their peers at software companies. When initially designing the product, they must consider exactly what sorts of outcomes they want clients to achieve. They have to consider from the outset (1) What indicators define success? and (2) How can I gather data on those indicators by building the right sensors, microprocessors, controls, ports, and other components into the product? Those decisions on design typically can’t be revisited later. Getting input early on from other departments—such as Support, Field Services, and Sales—will make a huge difference.

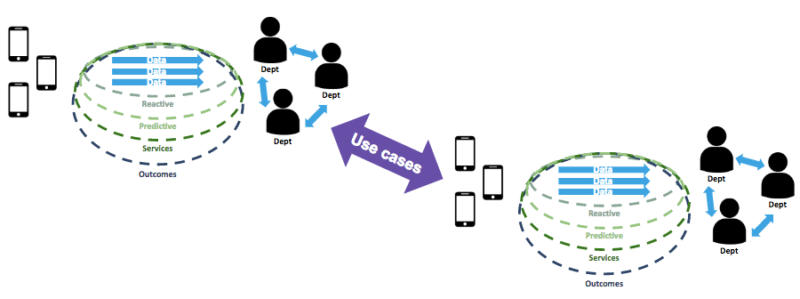

Layer #6: Across Companies

The opportunities to drive outcomes for clients multiply when manufacturers build devices that can communicate with each other through APIs. For example, a Nest thermostat can share data with a Kevo smart lock so that the thermostat can adjust the temperature when the homeowner enters the house. If Nest and Kevo collaborated on additional use cases, together they could expand the value that the client derives from the system of their devices.

Particularly in settings such as hospitals, cities, factories, and work sites, which may purchase connected devices from multiple manufacturers, the opportunities to drive synergies between devices continue to grow.

Here’s an example: PTC’s customer Teel Plastics, a custom extruded plastic tubing and profiles company, leveraged an IoT solution to connect disparate machines on their Baraboo, Wisconsin factory floor, including Programmable Logic Controllers from both Siemens and Allen-Bradley. In doing so, Teel Plastics improved factory efficiency (reducing setup times by 30%), reduced the risk of human error in shifting from manufacturing one recipe to the next, decreased asset downtime leveraging predictive maintenance, and ultimately produced greater output at a much higher quality.

This example shows the value of creating systems across vendors. When vendors don’t merely solve for Customer Success in the silo of their own products but instead work with each other (perhaps through the involvement of a third party), they can achieve much greater overarching outcomes for mutual customers.